Understanding Induction Copper Melting Furnace: A Comprehensive Guide

Induction copper melting furnaces stand at the forefront of modern industrial processes, offering unparalleled efficiency and precision in melting copper for various applications. Their significance spans across industries such as foundries, metalworking, and recycling, where the demand for efficient copper melting solutions continues to rise. In this comprehensive guide, we delve into the key features, customization options, and technological advancements of induction copper melting furnaces, shedding light on their crucial role in meeting industry demands.

Key Features and Components

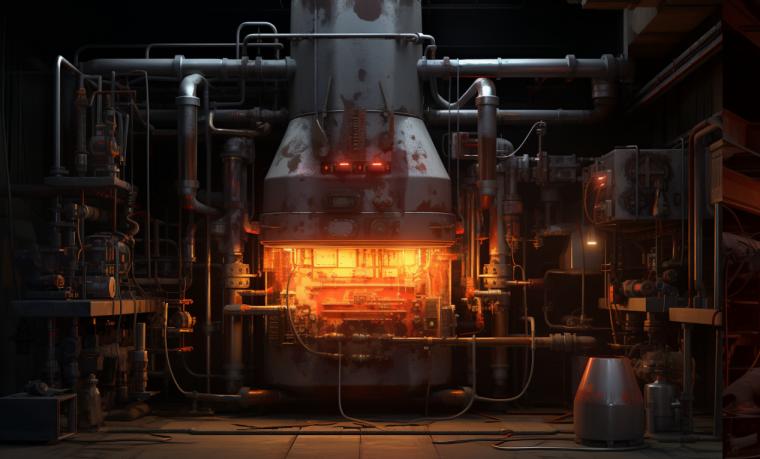

1.1 Components of Induction Copper Melting Furnaces

Induction copper melting furnaces comprise several essential components, including the coil, crucible, power supply, and cooling system. The coil generates electromagnetic fields for induction heating, while the crucible holds the copper material during melting. The power supply provides electrical energy to the coil, and the cooling system prevents overheating, ensuring continuous operation.

1.2 Features Enhancing Performance

These furnaces boast innovative features that optimize performance and productivity. Automatic temperature control mechanisms maintain precise melting temperatures, while energy optimization systems minimize power consumption. Remote monitoring capabilities allow for real-time supervision, ensuring efficient operation and timely maintenance.

Meeting Industry Demands: Tailored Solutions with Induction Copper Melting Furnaces

2.1 Understanding Industry Needs

Industries requiring copper melting solutions have diverse needs and challenges. Foundries, metalworking facilities, and recycling plants demand efficient and reliable melting processes to meet production targets and quality standards. Understanding these specific requirements is crucial for developing tailored solutions that address industry-specific challenges effectively.

2.2 Customization Options

Induction copper melting furnaces offer customization options to meet varying production requirements. These options include adjustable capacity to accommodate different production volumes, flexible designs for seamless integration into existing processes, and compatibility with various copper alloys. Such flexibility ensures that businesses can adapt their melting operations to changing demands and market trends.

2.3 Case Studies

For instance, in foundries, customized induction furnaces equipped with tilting mechanisms streamline the casting process, improving efficiency and reducing labor costs. Similarly, in metalworking applications, precise temperature control features ensure optimal material properties during annealing and heat treatment processes.

2.4 Benefits of Flexibility and Scalability

The flexibility and scalability of induction copper melting furnaces offer significant advantages for businesses of all sizes. Whether it’s a small-scale operation or an industrial-scale production facility, these furnaces can be tailored to meet specific needs. This scalability allows businesses to expand their operations or diversify their product lines without compromising efficiency or quality.

Innovative Features and Technology Advances in Induction Copper Melting Furnaces

3.1 Latest Advancements

Induction copper melting furnaces continue to evolve with the latest technological advancements. Automatic temperature control systems, energy optimization features, and remote monitoring capabilities are among the recent innovations driving efficiency and productivity in copper melting processes.

3.2 Automatic Temperature Control

Advanced temperature control algorithms ensure precise regulation of melting temperatures, resulting in consistent and high-quality output. These systems continuously monitor and adjust heating parameters to maintain optimal conditions throughout the melting process, minimizing material waste and maximizing productivity.

3.3 Energy Optimization

Energy optimization features optimize power usage, reducing operational costs and environmental impact. Variable frequency drives adjust power output based on melting requirements, ensuring efficient energy utilization and minimizing electricity consumption. This not only lowers operating expenses but also aligns with sustainability initiatives.

3.4 Remote Monitoring

Remote monitoring capabilities enable real-time supervision of furnace operations from anywhere with internet access. Cloud-based monitoring systems provide access to vital operational data, allowing for proactive maintenance and troubleshooting. Predictive analytics algorithms identify potential issues before they escalate, minimizing downtime and maximizing uptime.

Industry Applications of Induction Copper Melting Furnaces: From Foundries to Recycling

4.1 Examination of Diverse Applications

Induction copper melting furnaces have found widespread use across various industries due to their versatility and efficiency. Foundries rely on these furnaces for melting and casting metals into intricate shapes, while metalworking facilities utilize them for annealing and heat treatment processes. Moreover, recycling operations benefit from induction technology to melt down scrap copper into high-quality ingots for reuse in manufacturing. The diverse applications of induction copper melting furnaces underscore their importance in modern industrial processes.

4.2 Analysis of Industry-Specific Challenges and Solutions

Each industry faces unique challenges in the copper melting process, ranging from material handling issues to energy efficiency concerns. Induction technology addresses these challenges effectively by offering precise temperature control, minimizing material waste, and reducing energy consumption. Foundries benefit from the flexibility of induction furnaces to handle different metal alloys, while metalworking facilities appreciate the rapid heating and cooling cycles enabled by these furnaces. In recycling operations, induction technology allows for the efficient melting of scrap copper, promoting resource conservation and sustainability.

4.3 Potential for Expanding Applications and Market Growth

The potential for expanding applications of induction copper melting furnaces is vast, driven by technological advancements and evolving industry needs. As industries continue to prioritize efficiency, productivity, and sustainability, the demand for induction furnaces is expected to grow. Emerging sectors such as additive manufacturing and electronics manufacturing are also poised to adopt induction technology for copper melting processes. This presents significant market growth opportunities for manufacturers like Taizhou Hongkang Electric Co., Ltd., who specialize in producing high-quality induction furnaces tailored to diverse industry requirements.

Addressing Environmental Concerns: Sustainable Solutions with Induction Copper Melting

5.1 Discussion on Environmental Impact

Traditional copper melting methods often entail high energy consumption, emissions, and waste generation, contributing to environmental degradation. Induction copper melting furnaces offer a sustainable alternative by significantly reducing energy consumption and emissions while minimizing material waste.

5.2 Role in Reducing Energy Consumption and Emissions

Induction technology is inherently more energy-efficient than conventional melting methods, as it directly heats the material without the need for preheating or prolonged heating cycles. This results in lower energy consumption and reduced greenhouse gas emissions, aligning with sustainability goals and regulatory requirements.

5.3 Importance of Sustainability Initiatives

Sustainability initiatives and regulations play a crucial role in driving the adoption of cleaner technologies like induction copper melting furnaces. By investing in sustainable practices, businesses can not only reduce their environmental footprint but also enhance their reputation and competitiveness in the market.

5.4 Strategies for Integration into Eco-Friendly Production Processes

Integrating induction copper melting furnaces into eco-friendly production processes requires careful planning and implementation. Companies can adopt strategies such as optimizing furnace operation parameters, utilizing renewable energy sources, and implementing recycling programs for waste materials. These initiatives not only contribute to environmental conservation but also lead to cost savings and operational efficiency improvements.

Choosing the Right Induction Copper Melting Furnace for Your Business Needs

6.1 Guidance on Selection Factors

Selecting the right induction copper melting furnace is essential for maximizing productivity and minimizing operational costs. Businesses should consider factors such as capacity, power requirements, efficiency, and operational costs when evaluating furnace options.

6.2 Evaluation of Key Considerations

Capacity and power requirements should align with production demands, ensuring that the furnace can handle the desired workload efficiently. Efficiency ratings indicate the furnace’s energy consumption and operational costs, helping businesses make informed decisions about long-term investments.

6.3 Importance of Supplier Reputation and Support Services

Choosing a reputable supplier like Taizhou Hongkang Electric Co., Ltd., ensures the reliability and quality of the induction furnace. Additionally, comprehensive support services and warranty provisions offer peace of mind and assurance of ongoing technical assistance.

6.4 Tips for Optimization and ROI Maximization

Optimizing furnace performance through regular maintenance, training, and process optimization can maximize return on investment. By continuously monitoring and fine-tuning furnace operations, businesses can achieve higher productivity, lower operating costs, and extended equipment lifespan.

Conclusion

Induction copper melting furnaces, such as those manufactured by Taizhou Hongkang Electric Co., Ltd., play a pivotal role in modern industrial processes. Their advanced features, customization options, and technological advancements make them indispensable tools for meeting industry demands efficiently and effectively. As industries continue to evolve, the evolution of induction copper melting furnaces will undoubtedly shape the future of copper melting processes, driving innovation and sustainability across various sectors.