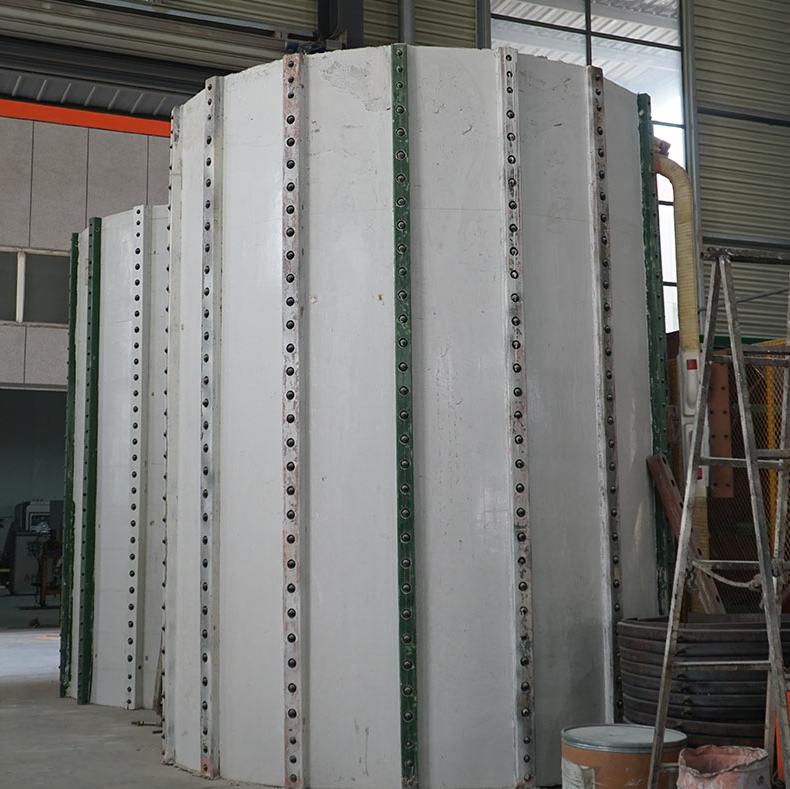

Large Capacity Furnace Body for Industrial Melting Operations

Introduction: Why Large Capacity Furnace Bodies Matter in Modern Industry

Industrial processes are constantly evolving, driven by the need for greater efficiency, lower costs, and higher output. One pivotal component that has transformed large-scale smelting and refining operations is the large capacity furnace body. But what makes it so indispensable? Imagine a furnace capable of melting tons of metal in a single operation while ensuring minimal energy consumption and consistent quality. This is not a vision of the future—it’s the reality enabled by advanced large capacity furnace bodies, such as the Parallel Resonance Large Capacity Melting Furnace.

This blog will delve into the unique capabilities and applications of these industrial giants, highlight their benefits for diverse sectors, and explore why companies like Taizhou Hongkang Electric Co., Ltd. are leading the way in providing these cutting-edge solutions.

Large Capacity Furnace Body: An Integral Component for Large-Scale Smelting Operations

Large-scale smelting and refining processes require specialized equipment capable of handling substantial quantities of raw materials. This is where the large capacity furnace body comes into play.

High Capacity and Versatility for Heavy-Duty Operations

The Parallel Resonance Large Capacity Melting Furnace, for instance, is designed to handle up to 90 tons of molten metal in a single batch. Its advanced design enables it to melt a wide range of metals, including steel, iron, copper, aluminum, silicon, and manganese. This flexibility makes it an ideal choice for industries ranging from automotive to aerospace manufacturing, where different materials need to be processed efficiently and in large volumes.

Efficiency Through Advanced Technology

What sets the Parallel Resonance Furnace apart is its use of parallel resonance technology. This approach ensures that the electrical impedance of the furnace is matched with the power supply, resulting in optimal energy transfer. The result? Superior heating efficiency, reduced power consumption, and a stable melting process. The furnace operates at power levels between 8000kW and 24000kW, making it one of the most energy-efficient options for large-scale metal melting available on the market.

Ideal for Continuous Production Lines

In addition to its melting capabilities, the furnace’s large capacity allows for longer operational cycles without interruptions. This feature is particularly valuable in facilities where downtime must be minimized to maintain high levels of productivity and profitability. Industries involved in continuous production lines, such as foundries and steel mills, benefit immensely from the reliable performance of large capacity furnace bodies.

Reducing Downtime and Maximizing Uptime with Large Capacity Furnace Bodies

One of the primary challenges faced by industrial operators is maintaining a high level of productivity while minimizing unplanned shutdowns. A large capacity furnace body like the Parallel Resonance Furnace addresses these concerns effectively.

Robust Design for Reliable Operations

The furnace’s robust construction ensures that it can withstand the high thermal and mechanical stresses associated with continuous metal melting. The high-capacity melting chamber is designed for durability, minimizing wear and tear and reducing the need for frequent maintenance. As a result, industries can benefit from increased operational uptime and fewer disruptions to production schedules.

Full Digital Control System for Precise Management

The incorporation of a full digital control system adds another layer of reliability and ease of operation. This system allows operators to monitor and control the furnace parameters in real-time, ensuring optimal performance at all times. Any deviations from standard operating conditions can be quickly identified and corrected, reducing the risk of costly downtime and ensuring a consistently high-quality melt.

Energy Efficiency and Cost Savings

Reducing downtime also means reducing energy consumption. Because large capacity furnace bodies like the Parallel Resonance Furnace are designed for efficiency, they require less energy per ton of metal melted compared to smaller, less advanced furnaces. This efficiency translates directly into lower operating costs and a smaller carbon footprint, making them a preferred choice for companies looking to improve both their bottom line and environmental impact.

Large Capacity Furnace Body: The Backbone of Efficient Industrial Heat Treatment

Heat treatment is a crucial step in metal processing, affecting everything from material properties to final product quality. The large capacity furnace body serves as the backbone of this process in industrial-scale operations.

Uniform Heating for Superior Material Properties

Achieving uniform heating is critical during heat treatment, as any temperature variations can lead to inconsistent material properties. The Parallel Resonance Furnace’s advanced control systems and large melting chamber ensure that heat is evenly distributed throughout the metal mass, resulting in a more consistent final product. This uniformity is essential for applications where the mechanical strength and durability of the material are paramount.

Scalability and Adaptability

The large capacity furnace body is not just a static piece of equipment; it’s adaptable to a range of heat treatment processes. Whether it’s annealing, hardening, or tempering, these furnaces can be fine-tuned to meet the specific requirements of different metals and alloys. This adaptability makes them a versatile tool for manufacturers who need to process a variety of materials without investing in multiple specialized furnaces.

Supporting Sustainable Production Practices

As industries place more emphasis on sustainable production practices, the energy-efficient design of large capacity furnace bodies contributes to a reduction in overall energy consumption. The ability to process large volumes of metal with minimal energy waste aligns with the goals of reducing greenhouse gas emissions and promoting resource efficiency.

How a Large Capacity Furnace Body Can Transform Your Industrial Operations

Upgrading to a large capacity furnace body can bring about transformative changes to any industrial operation, from increased output to improved material quality.

Boosting Production Capacity

Large capacity furnaces, such as parallel resonance furnaces, range in capacity from 25 to 90 tonnes. They allow the industry to process larger quantities of metal. Increased capacity reduces the number of melting cycles required. This frees up resources and time for other processes, ultimately increasing productivity.

Enhancing Product Quality

The precise control over melting and heat treatment conditions ensures that the end products meet the highest standards of quality. This consistency is particularly important in industries such as automotive and aerospace, where even minor material defects can have serious consequences.

Lowering Operational Costs

The combination of high efficiency, minimal downtime, and reduced energy consumption results in lower operational costs. By reducing the number of melting cycles and optimizing energy use, companies can achieve significant savings over the long term, making the initial investment in a large capacity furnace body a financially sound decision.

The Future of High-Temperature Processing: Innovations in Large Capacity Furnace Bodies

As the industrial landscape continues to evolve, so do the technologies behind large capacity furnace bodies. Innovations are paving the way for even more efficient and sustainable operations.

Advanced Control Systems and Automation

Future advancements are likely to include more sophisticated control systems, enabling even greater automation and precision. These systems will not only monitor and adjust furnace parameters but also integrate predictive maintenance capabilities, further minimizing downtime and extending the life of the equipment.

Enhanced Energy Efficiency and Environmental Compliance

Newer models of large capacity furnace bodies are expected to incorporate technologies that enhance energy efficiency even further, such as regenerative heating systems and advanced insulation materials. These innovations will help industries comply with increasingly stringent environmental regulations while maintaining high production standards.

Customization for Specific Industrial Needs

Customization will play a more significant role as well. Large capacity furnace bodies will be designed to cater to the unique requirements of different industries, from the composition of the melting medium to the specific heat treatment cycles required. This level of customization will enable manufacturers to achieve optimal results for their specific applications.

Conclusion: Choosing the Right Large Capacity Furnace Body Supplier

For industries looking to invest in large capacity furnace bodies, partnering with a reliable supplier like Taizhou Hongkang Electric Co., Ltd. is crucial. With their expertise and commitment to innovation, they provide state-of-the-art solutions that meet the diverse needs of various industries.

By selecting the right large capacity furnace body, companies can unlock new levels of efficiency, quality, and profitability in their operations, making this investment a cornerstone of their long-term success.