IGBT Series Resonant Mini-Melt Furnace: Advanced Melting Technology for Precision and Efficiency

Precision and efficiency are important in melting processes. They help produce high-quality metal and save energy. The IGBT Series Resonant Mini-Melt Furnace is a new solution that addresses these needs. This furnace leads in industrial metal melting technology. It provides excellent efficiency, precision, and reliability. Its main benefits are precise control, energy savings, and versatility. With this furnace, industries can improve performance and reduce costs.

Understanding IGBT Technology

What is IGBT?

IGBT stands for Insulated Gate Bipolar Transistor. It is a type of power semiconductor device. IGBT plays a key role in modern melting technologies. It controls the electrical power in melting furnaces. This control helps in precise heating and energy management.

How IGBT Improves Melting Processes

IGBT technology enhances the melting process compared to traditional methods. Traditional furnaces often use less efficient power control. With IGBT, power flow is managed better. This leads to more consistent heating. As a result, the melting process becomes faster and more reliable.

Benefits of IGBT in Power Control and Energy Efficiency

Using IGBT offers several benefits. First, it controls power flow accurately. This precision reduces energy waste. Second, IGBT improves energy efficiency. Less energy is needed to achieve the desired temperature. Finally, better control leads to higher-quality melts. This means fewer defects and better product quality.

How the Series Resonant Design Works

What is Resonant Circuit Design?

The series resonant design uses a resonant circuit. A resonant circuit includes inductors and capacitors. These components work together to deliver power efficiently. This design helps in smooth power delivery to the furnace. It minimizes energy loss during the process.

Role of Resonant Frequency in Heating

The resonant frequency is crucial in this design. It determines how efficiently power is transferred. By matching the resonant frequency, the furnace achieves optimal heating. This ensures that the metal melts evenly and quickly. Controlled heating also prevents overheating and material waste.

Comparison with Non-Resonant Designs

Compared to non-resonant designs, the series resonant design offers higher precision. Non-resonant furnaces often have uneven heating. This can lead to inconsistent melts and higher energy use. The resonant design reduces waste by targeting the exact power needed. It also provides more consistent and higher-quality results.

Mini-Melt Furnace: Design and Features

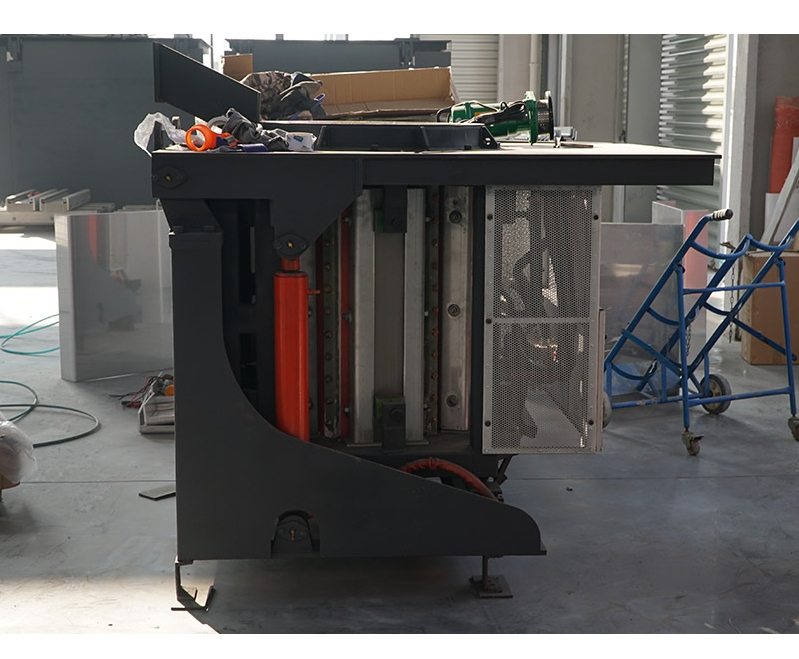

Compact and Space-Saving Design

The Mini-Melt Furnace is designed to be compact. Its small size saves space in industrial settings. This makes it ideal for facilities with limited room. Despite its size, it does not compromise on performance. The furnace fits easily into various production environments.

Key Features: Temperature Control and Uniform Heating

This furnace has precise temperature control. Operators can set exact temperatures for different metals. Uniform heating ensures that the metal melts evenly. This leads to consistent quality in the final product. The precise melt rate allows for better control over the production process.

Compatibility with Different Materials

The Mini-Melt Furnace is compatible with various materials. It can handle different types of metals and alloys. This flexibility makes it suitable for multiple melting processes. Industries can use the furnace for a wide range of applications without needing different equipment.

Applications of the IGBT Series Resonant Mini-Melt Furnace

Industries That Benefit

Many industries benefit from this furnace. Foundries use it for casting metals. Steel mills rely on it for efficient steel production. Automotive manufacturers use it for alloy production. Other industrial sectors also find it valuable for their melting needs.

Precision Casting and Alloying

Precision casting is a key application. The furnace provides the exact temperatures needed for high-quality casts. Alloying is another important use. It allows for the precise mixing of different metals. This results in alloys with desired properties for various applications.

Examples of Use Cases

Several industries have seen positive impacts from this technology. Foundries report faster melting times and better-quality casts. Steel mills experience lower energy costs and higher production rates. Automotive companies benefit from consistent alloy properties, improving vehicle performance and safety.

Advantages of Using an IGBT Series Resonant Mini-Melt Furnace

Energy Efficiency and Lower Costs

This furnace is highly energy-efficient. It uses less power to achieve the same melting results as traditional furnaces. Lower energy use leads to reduced operational costs. Businesses save money on their energy bills while maintaining high production levels.

Enhanced Precision and Control

Precision control is a major advantage. Operators can manage temperatures and power flow accurately. This leads to high-quality melts with fewer defects. Enhanced control also allows for better consistency in production batches.

Environmental Benefits

Using this furnace has positive environmental impacts. It produces lower emissions compared to older models. Reduced energy consumption means a smaller carbon footprint. These benefits help companies meet environmental regulations and promote sustainable practices.

Compact Design for Easy Installation

The compact design makes installation simple. It requires less space, making it suitable for smaller facilities. Easy installation reduces setup time and costs. The furnace can be quickly integrated into existing production lines, minimizing downtime.

Final Thoughts

The Hongkang IGBT Series Resonant Mini-Melt Furnace is a top choice for metal melting needs. It uses advanced IGBT technology to control power and save energy. The resonant design ensures efficient and even heating. Its compact size fits well in any facility. This furnace works with many types of metals, making it very flexible. Users benefit from lower energy costs and high-quality melts. It also helps the environment by reducing emissions and energy use. Hongkang’s furnace is easy to install and operate, perfect for small and large operations alike.

Take Action Today! Upgrade to the Hongkang IGBT Series Resonant Mini-Melt Furnace. Improve your melting process, save energy, and boost your production quality. Contact us now to learn more and get started!