Parallel Resonance Large Capacity Melting Furnace

The Parallel Resonance Large Capacity Melting Furnace represents a cutting-edge solution for the melting and refining of metals on an industrial scale. This furnace operates on the principle of parallel resonance, where the electrical impedance of the furnace matches that of the power supply, resulting in optimal energy transfer and heating efficiency. It features advanced temperature control systems to ensure precise regulation of the melting temperature, leading to consistent quality and metallurgical properties of the melted metal

Features of the Parallel Resonance Large Capacity Melting Furnace:

-

High Capacity: Designed to handle large quantities of metal, this furnace is ideal for high-volume melting operations in foundries and metalworking facilities.

-

Efficient Heating: The parallel resonance technology ensures efficient energy transfer, leading to rapid and uniform heating of the metal charge within the furnace.

-

Temperature Control: Advanced temperature control systems allow for precise regulation of the melting temperature, ensuring the consistent quality and metallurgical properties of the melted metal.

-

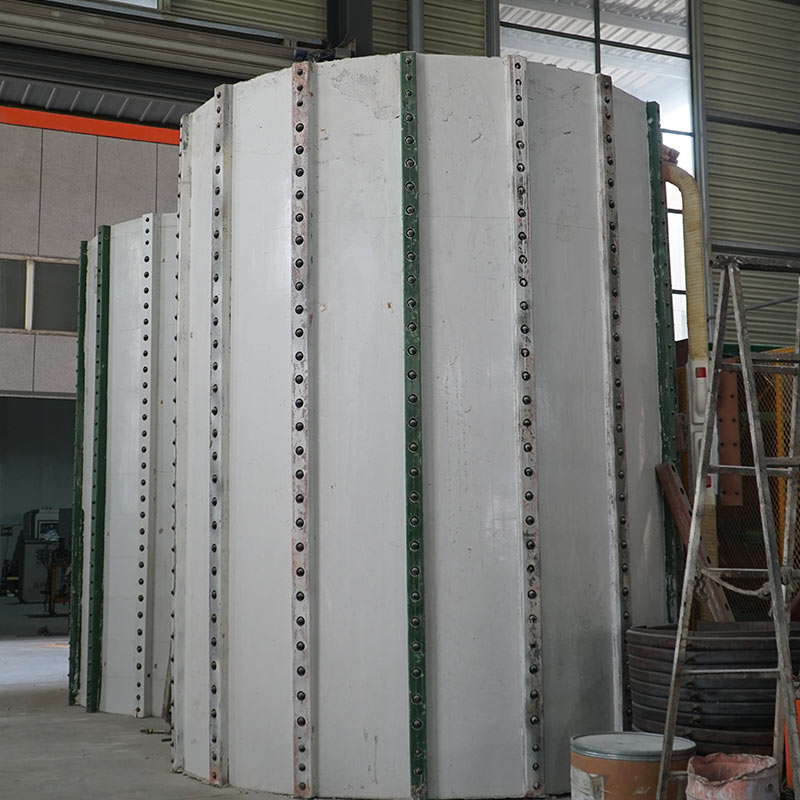

Robust Construction: Built with durable materials and components, the furnace can withstand the rigors of continuous operation in demanding industrial environments.

-

Safety Features: Equipped with safety systems such as temperature sensors, overcurrent protection, and emergency shutdown mechanisms to ensure safe operation and prevent accidents.

Why trust hongkang frequency ?

- INTRODUCTION

The Parallel Resonance Large Capacity Melting Furnace is an advanced industrial furnace specifically designed for melting and refining large quantities of metal alloys. It operates on the principle of parallel resonance, where the electrical impedance of the furnace matches that of the power supply, resulting in optimal energy transfer and heating efficiency. This furnace is equipped with a high-capacity melting chamber capable of accommodating large volumes of metal, making it suitable for industrial-scale metal melting operations.

- Power: 8000KW-24000kW.

- Capacity: (25T-90T)1 furnace.

- Melting medium: steel, iron, copper, aluminum, silicon, manganese, etc.

- Small size, high efficiency, and good energy-saving performance.

- Full digital control system, reliable operation, easy to operate.

Application

The Parallel Resonance Large Capacity Melting Furnace finds extensive applications across various industries due to its versatility, efficiency, and capacity for large-scale metal melting operations. Here are detailed applications of this furnace:

Foundries and Metal Casting: One of the primary applications of the Parallel Resonance Furnace is in foundries and metal casting facilities. It is used for melting and refining various metals, including iron, steel, aluminum, and copper, to produce castings for automotive, aerospace, construction, and other industries.

Steel Production: In steel mills and metallurgical plants, the Parallel Resonance Furnace plays a crucial role in the production of steel. It is used for melting scrap metal and alloying elements to produce molten steel, which is then further processed through refining and casting processes.

Automotive and Aerospace Manufacturing: The Parallel Resonance Furnace finds application in the manufacturing of automotive and aerospace components. It is used for melting and alloying metals such as aluminum, titanium, and high-strength steels to produce engine parts, structural components, and other critical components.

Heavy Machinery and Equipment Production: Industries involved in the production of heavy machinery and equipment, such as mining, construction, and agriculture, utilize the Parallel Resonance Furnace for melting and casting metal components. T