Series Resonance One Tow N Medium Frequency Melting Furnace

A Series Resonance Medium Frequency Melting Furnace is a specialized industrial furnace designed for melting metals using medium-frequency induction heating technology. These furnaces operate based on the principle of series resonance, where the furnace coil and capacitor form a resonant circuit at a specific frequency.

Features of Series Resonance Medium Frequency Melting Furnaces:

-

Efficient Heating: The resonance design allows for efficient energy transfer from the power supply to the metal charge, resulting in rapid and uniform heating.

-

Precise Temperature Control: Advanced temperature control systems ensure accurate monitoring and regulation of the melting process, allowing for consistent quality and reproducibility.

-

High Power Density: Medium frequency induction heating offers high power density, enabling quick melting of metal charges while minimizing energy consumption.

-

Compact Design: These furnaces often feature a compact and space-saving design, making them suitable for various industrial applications with limited space.

-

Safety Features: Built-in safety features such as overcurrent protection, overvoltage protection, and water cooling systems ensure safe operation and prevent equipment damage.

-

User-Friendly Interface: Intuitive control panels and user-friendly interfaces facilitate easy operation and monitoring of the melting process.

-

Versatility: Series Resonance Medium Frequency Melting Furnaces can accommodate a wide range of metals and alloys, making them suitable for diverse melting applications across industries.

Why Trust Series Resonance Medium Frequency Melting Furnaces:

Series Resonance Medium Frequency Melting Furnaces are trusted for their efficiency, reliability, and precision in metal melting applications. They offer fast heating, precise temperature control, and consistent performance, making them indispensable in foundries, metal processing plants, and other industrial settings.

Manufactured by reputable companies with extensive experience in furnace technology, these furnaces undergo rigorous testing and quality control measures to ensure optimal performance and durability. Additionally, comprehensive technical support and after-sales service provided by trusted manufacturers ensure smooth operation and maximum uptime for users.

- INTRODUCTION

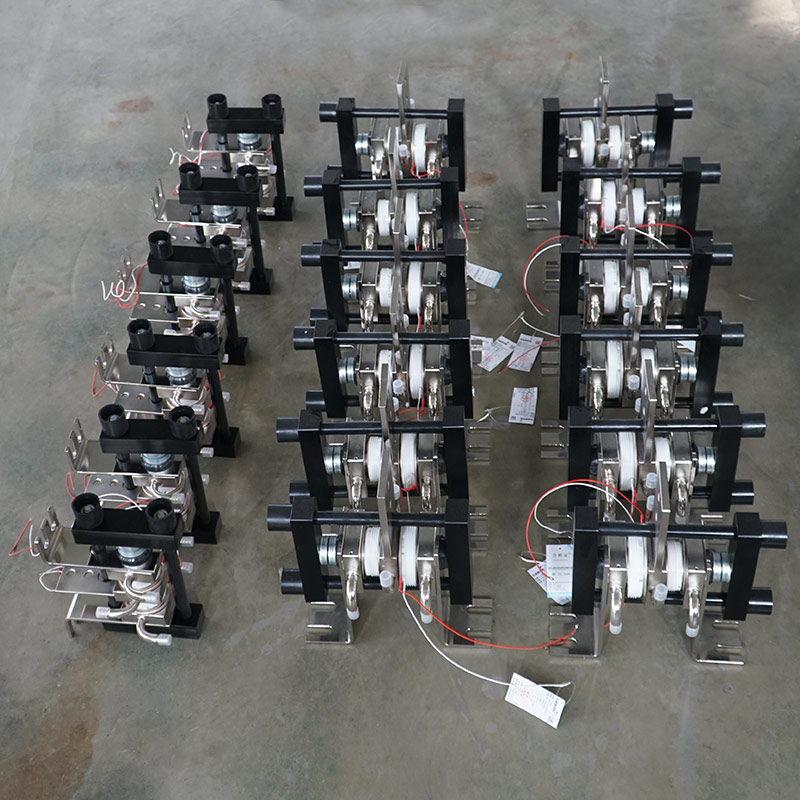

Series resonance a drag N intermediate frequency furnace melting furnace, can be a medium frequency power cabinet drag 1, 2, 3… N melting furnaces work at the same time to achieve the whole process of flow production, which can greatly improve production efficiency, and its power cabinet can be IGBT module and thyristor two types.

Application

-

Jewelry Manufacturing: Used for melting precious metals such as gold, silver, platinum, and palladium to create jewelry items and decorative pieces.

-

Die Casting: Employed in die casting operations for melting and casting metals into intricate shapes and designs used in automotive, aerospace, and consumer goods industries.

-

Steelmaking: Utilized in steelmaking processes for melting and refining scrap steel to produce new steel products with specific compositions and properties.

-

Alloy Production: Used for melting and alloying different metals to create specialized alloys used in various industries, including automotive, aerospace, and electronics.

-

Research and Development: Employed in research laboratories and academic institutions for studying material properties, alloy development, and process optimization in metallurgical research.

| Model | BE-W300 | BE-W500 |

| Name | 300W Laser welding machine | 500W Laser welding machine |

| Machinery Part | Laser cavity length of 1100 mm, the laser head can rotate 360 degrees. | |

| Working Area | 750*1000MM | |

| Load Bearing | ≤200KG | |

| Machine Power Supply | 220V±10%/50/60Hz | 380V±10%/50/60Hz |

| Laser Type | Nd:YAG impulse xenon lamp | |

| Spot Size | 0.2-3.0mm | |

| Laser Wave Length | 1064nm | |

| Impulse Width | ≤10ms | |

| Laser Power | 300W | 500w |

| Single Pulse Energy | 90J | 120J |

| Impulse Rate | ≤50Hz | ≤100Hz |

| Laser Output Focal Length |

150-250mm Fiber Lead Head 120mm |

150-250mm Fiber Lead Head 120mm |

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-W300/W500 | 1.9m×0.83m×1.32m, 2.08CBM 0.65m×0.55m×1.08m, 0.39CBM |

370KG |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craftcase. |

-

yoon Hong Gun

★★★★★Post a review on Aug 21, 2022 From Republic Of Korea

The CCD display is very clear. It is very easy to weld, and the operation is not difficult. We learned from video and manual.

-

Pavel Voronov

★★★★★Post a review on Aug 21, 2022 From Spain

It’s more convenient to use. I was worried about the operation before buying. Now we use it well.

-

Jonnathan Quiel

★★★★★Post a review on Aug 21, 2022 From Costa Rica

The advertising sign laser welding machine is very easy to use and easy to operate. I have never been used laser welding before. I didn’t expect it to be so simple and easy to learn. The welding effect is good and accurate.

-

romel huaraca

★★★★★Post a review on Aug 21, 2022 From Peru

The machine puts into production immediately. The welding scar is small, and the welding seam is beautiful. The efficiency is greatly improved.

-

Sal Mey

★★★★★Post a review on Aug 21, 2022 From Cambodia

The laser welding machine weld smooth. We produced beautiful signs.